Alleviation: An International Journal of Nutrition, Gender & Social Development, ISSN 2348-9340

Volume 2, Number 2 (2015) : 1-7

©Arya PG College, Panipat & Business Press India Publication, Delhi

www.aryapgcollege.com, www.apcjournals.com

Antimicrobial Finished NYCO for Safe Indian Military

1. Ratna Tiwari, 2. Sneha Sharma,3. Dr. Sandhya Kaushik & 4. Dr. MS Parmar

1. Lecturer , Directorate of Education, Delhi, India

2. Ex-Student, VMLG College, Ghaziabad (Uttar Pradesh), India

3. Lecturer, Department of Home Science,VMLG College, Ghaziabad (Uttar Pradesh), India

4. Assistant Director, NITRA Ghaziabad (Uttar Pradesh), India

E-mail: ratnamishra01@gmail.com

Introduction

In the present day world, most of us are very conscious about our hygiene and cleanliness. Clothing and Textile are a very suitable media for the growth of the microorganisms. They can act as the carriers of microorganisms such as pathogenic bacteria, odour generating bacteria and mould fungi.

Microbial infestation poses danger to both living and non-living matters. Microorganism growth is the factor that has resulted in development of Protective Clothing. Clothing and textile materials are not only the carriers of microorganisms such as pathogenic bacteria, odour generating bacteria and mould fungi, but also good media for the growth of the microorganisms. Obnoxious smell form the inner garments such as socks, spread of diseases, staining and degradation of textiles are some of the detrimental effects of bad microbes (Sathianarayanan et al 2010).

Military and Paramilitary Uniform

Textiles and garments provide the barrier between the user and the surrounding environment. With the variation in the surrounding environment, the need of the barrier textiles or garment also varies.

One of the important examples of the barrier clothing is military clothing. Military clothing is an integral part of a soldier’s fighting kit. It plays a key role in protecting soldiers during combat and must therefore perform several functions in the most rugged of wearing conditions. At the same time, it must remain durable. If today’s military clothing is compared with First World War clothing worn by soldiers, in appearance and performance characteristics, it can be seen that there is a sharp contrast.

Historically, military uniforms were made of heavy cotton twill or duck fabric. The heavier the fabric, the more durable it was. These types of fabrics were hot to wear, became heavier when wet and were slow to dry. Cotton fabrics rapidly looked like they were slept in even when heavily starched. Pure synthetic fibers had a good wear life but the fabric tended to be hot and did not absorb sweat.

The combat uniform used in most of the Military and paramilitary forces are made of nylon and cotton blended material and these are mostly camouflage pattern printed. Currently nylon- cotton blended fabric in two compositions, viz. 50/50 and 30/70 is predominantly in use for development of Combat clothing for Military and Paramilitary troops in India. The popularity of nyco for Combat clothing is due to the fact that it is available in bulk quantity easily at a considerably competitive price. The nylon - cotton blended fabric is made in plain, rip-stop or twill weave (3x1, broken etc.).

During the early 1940 s, the US army Quartermaster Crops collected and compiled data on fungi, yeast and algae isolated from textiles in tropical and subtropical areas throughout the world. Cotton duck, webbing and other military fabrics were treated with mixtures of chlorinated waxes, copper and antimony salts that stiffened the fabrics and gave them a peculiar odor. At the time, potential polluting effects of the application of these materials and toxicity-related issue were not a major consideration.

After World War II and as late as the mid-to-late 1950s, fungicides used on cotton fabrics were compounds such as 8-hydroxygiunoline salts, copper naphthenate, copper ammonium fluoride and chlorinated phenals. As the government and industrial firms became more aware of the environmental and workplace hazards, these compounds caused, alternate products were sought.

Microbes are the tiniest creatures not seen by the naked eye. There are various types of microorganisms like bacteria, yeast, fungi, algae and viruses. Fungi, molds or mildew are complex organisms with slow growth rate. Fungi are active at a pH level of 6.5.

Algae are typical microorganisms, which are either fungal or bacterial. Algae require continuous sources of water and sunlight to grow and develop darker stains on the fabrics. Algae are active in the pH range of 7.0-8.0

Textile materials can be exposed to contamination with microbes (Bacteria, fungi, algae) during production, usage or storage. Natural fibres are particularly prone to microbial attack as they are readily digestible by bacteria and fungi but the synthetic fibres are not completely immune either as they might contain some additives that may be a nutrient for microbes. Cotton is more likely to be attacked by fungi. Some of the possible effects of micro-organisms on textiles are:

• Bad odour.

• Discoloration.

• Unsightliness or staining of the fabric.

• A slick slimy handle.

• Loss of functional properties like elasticity.

• Reduction in tensile strength.

• Decrease in the life of the textiles, especially cotton and wool.

Keeping above points in mind, the present study was undertaken in order to obtain antimicrobial finish on military and paramilitary forces. The present study was undertaken with the following objectives in mind:

1) To apply the antimicrobial finish (Clove Oil and N9 Silver based) on military fabric.

2) To test the antimicrobial property against microbes (Staphylococcus, Klebsiella and Candida).

3) To compare the antimicrobial properties of Clove Oil and Silver based N9 finish.

Methodology

This study was carried out in 3 phases i.e.

Phase-1

Selection of area: The experiments were carried in the laboratories of NITRA (Northern Indian Textile Research Association) Ghaziabad, Pathology Lab of Dr. Parul, Near Santosh Medical Hospital Ghaziabad and Chest clinic New Delhi (Mehrauli).

Selection of the base material: NYCO (Nylon6, 6 and cotton blend) fabric was used in this thesis. NYCO fabric is soft in handle and more spacious in their structure so that antimicrobial finish can easily penetrate in between the spaces of fabric. NYCO fabric has good stretchability, absorbency, fitness, durability, tenacity and comfort, thus taken for study.

Collection of raw Material : The raw material was collected as follows:

• Fabric: NYCO fabrics were collected from NITRA.

• Antimicrobial Finish: Antimicrobial finish was brought from Resin Pvt. Ltd (Bangalore).

• Bacteria and Fungus: They were carried from T.B Hospital, Dr. Mynaidu (Mehrauli, New Delhi).

• Clove Oil: Clove oil was purchased from Chemist Shop of Delhi.

• Prepared Petri Plates: Blood Agar Plates, Macconkey Agar Plates, Sabouraud Dextrose Agar Plates.

These Prepared Petri plates were carried out from Krill Green Medical Devices (Mayur Vihar, New Delhi).

Selection of the method and its sub-technique: To conduct this study, scientific and experimental methods were used for investigation and research. Scientific methods help to collect information very scientifically. The experiment method is more precise and accurate.

Preparation of fabric: The fabric was scoured in water by adding neutralize soap solution

before application of finish.

Selection of techniques: In this study two techniques (Pad dry cure & Exhaust) were used for application of antimicrobial finish.

Phase 2

Application of antimicrobial finish: The following finishes were applied:

(i) Natural finish.

(ii) Chemical finish.

(i) Natural finish: Clove oil was applied. The recipe of clove oil was:

Fabric type: NYCO.

Clove oil: 1-2 per cent (Dosage is taken according to weight of fabric).

Methanol: 50ml.

Procedure: The following procedure was applied:

• Two conical tight capped flasks were taken.

• In the first flask, 50ml methanol and 1gram of fixer was taken. This mixture was shaken continuously till the solution was dissolved.

• Clove oil was added in this solution.

Pad dry cure method: Fabric was dipped into the padding bath.

• Then fabric was passed through the padding mangle by applying pressure.

• The Pad pressure was 0 per cent, 20 per cent and 40 per cent respectively.

• Drying was carried out by stentering machine.

• Curing temperature was 130°C to 140°C.

(ii) Chemical finish: N9 Silver finish was applied (Application through Resin). The recipe of N9 Silver finish was:

Fabric type: NYCO

Dosage of N9 Silver:1 per cent - 2 per cent (Dosage is taken according to weight of fabric).

Dosage of SEA (Surface Enhancing Agent): 1 per cent (Dosage is taken according to weight of fabric).

pH: 5.5 to 6.

MLR: 1:10.

Temperature: Room temperature.

Time: 30 minute and after application kept for line drying.

Procedure: The following procedure was applied:

• Acidified bath water was made first and SEA (In the form of a gel)was added.

• Stirring continuously for several minutes was required to make a homogenous emulsion.

• Recommended quantity of N9 Pure Silver was added.

• It was thoroughly mixed to get a pale yellow colored homogenous solution and then remaining water was added.

• Application was done by exhaust method and exhaustion was complete when it was changed from a light yellow colored, hazy solution to a colorless transparent solution.

Test organisms (AATCC-100-2004): Bacteria (Staphylococcus species, Gram positive organism, Klebsiella species, Gram negative organism) and fungus (Candida) were tested against antimicrobial finish.

Culture medium: Nutrient broth was prepared as follows:

Peptone (Bacto peptone): 5 gm.

Beef extract: 3gm.

Distilled water: 1000 ml. The following procedure was applied:

• Heated to a boil to disperse ingredients. Adjust to pH 6.8 ± 0.1 with 1 N sodium hydroxide (NaOH) solution. (This is not necessary if prepared, dehydrated medium is used).

• Dispensed in 10 ml amounts in conventional bacteriological cultural tubes (i.e. 125 x 17 mm). Plug and sterilize at 103 kPa (15 psi) pore 15 min.

• Added 1.5percent bacteriological agar to nutrient (Or appropriate) broth. Heated to boiling. Checked pH and adjusted to using NaOH solution if necessary. Dispensedin 15 ± 1 ml amounts in conventional bacteriological culture tubes. Plugged and sterilized at 103 kPa (15 psi) for 15 min.

Slurry inoculums’ carrier (For hydrophobic fabrics)

Sodium chloride: 8.5 g.

Agar : 3.0 g.

Distilled water: 1000 ml.

Maintenance of culture of test organisms: Using a 4mm inoculating loop, the culturewas daily transferred in nutrient broth (Or appropriate medium) for not more than two weeks. At the end of two weeks, a fresh transplant from stock culture was made. Culture was incubated at 37+_ 2º c (99 ± 3º F) or other optimal temperature.

Stock cultures should be maintained on nutrient or appropriate agar slants and stored at 5±1 ºc (41± 2º f) and should be transferred once a month to fresh agar.

Phase 3

Qualitative testing: A clear zone of inhibition ensures antibacterial activity of finish since zone of inhibition occurs as a result of the diffusion of an antimicrobial agent from the finish. An inhibition zone >2mm. indicated good antibacterial effect.

Procedure

• Agar plates were swabbed with the broth culture incubated for 24 hours.

• After swabbing the agar plates with respective bacteria used in the study, the treated samples of 2cm diameter were pressed against agar surface in the middle of the plate with a pair of forceps which has been sterilized in the flame and then air cooled immediately before use.

• These plates were then incubated at 370C for 24 hours.

After 24 hours, the incubated plates were examined for clear zone of inhibition. The average width of the zone of inhibition on either side of the fabric was calculated using the following equation:

W= (T-D)/2

Where,

W= Width of Inhibition (mm).

T= Total Diameter of Fabric and Clear Zone (mm).

D= Diameter of Well Created (mm).

Precautions: The following procedure was applied:

• The whole testing was conducted in laminar chamber.

• All apparatus was sterilized before using.

• After testing was completed, material was disposed off in accordance with the regulation prescribed for the deactivation of the biological material to ensure environment and human safety.

• Some of bacteria used in this test were capable of infecting humans and producing diseases. Therefore every necessary and reasonable precaution was taken to eliminate this risk to laboratory personnel and to personnel in associated environment.

• All chemicals were handled with care.

• An eyewash/safety shower was also kept nearby for emergency use.

Results and Discussion

Testing Antimicrobial Property of Natural Finish on Fabric 30:70NYCO

The zone of inhibition of Staphylococcus and Klebsiella was good in 2 per cent finish in comparison to 1 per cent finish (Table/Fig 1). But the zone of inhibition of candida in 1 per cent was less in comparison to 2 per cent finish. There was no zone of inhibition for Candida in controlled condition. So, 2 per cent finish was better than 1 per cent finish and controlled condition.

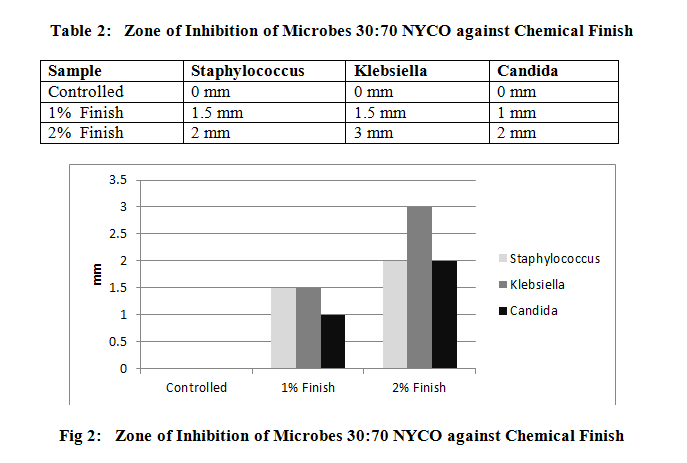

Testing Antimicrobial Property of Chemical Finish on Fabric 30:70NYCO

The zone of inhibition of Staphylococcus was good for 2 per cent finish in comparison to 1 per cent finish (Table/Fig 2). But the zone of inhibition of candida in 1 per cent was less in comparison to 2 per cent finish. There was no zone of inhibition for all microbes in controlled condition. It can be said that 2 per cent finish was better than 1 per cent finish as well as controlled condition for all microbes.

Comparison between Natural and Chemical of 30:70 NYCO against Staphylococcus

It can be observed in the Table /Fig 3 that the zone of inhibition of Staphylococcus in natural finish was excellent for 2 per cent finish in comparison to chemical finish.

In case of controlled condition, the zone of inhibition of Staphylococcus was absent in natural as well as chemical antimicrobial finish in case of controlled condition.

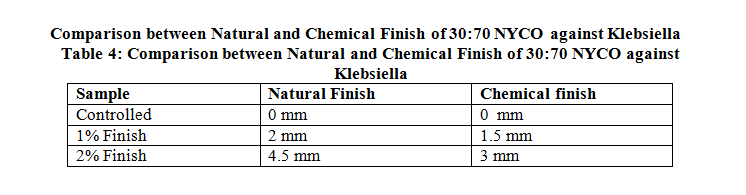

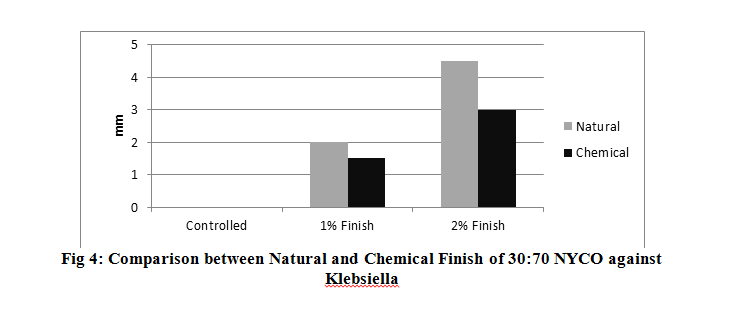

The zone of inhibition of Klebsiella was good in 2 per cent natural and chemical antimicrobial finish (Table/Fig 4). In case of 1 per cent natural antimicrobial finish, the zone of inhibition of Klebsiella was good for natural finish in comparison to chemical antimicrobial finish. There was no zone of inhibition of Klebsiella in controlled condition in both finish.

Comparison between Natural and Chemical Finish of 30:70 NYCO against Candida

The zone of inhibition of Candida was absent in controlled condition of natural and chemical antimicrobial finish (Table/Fig 5). In case of 1 per cent natural and chemical antimicrobial finish, the zone of inhibition of Candida was less for 1 per cent in comparison to 2 per cent natural and chemical antimicrobial finish. It can be said that 2 per cent natural antimicrobial finish had good zone of inhibition in comparison to chemical finish.

Conclusions

Textile materials can be exposed to contamination with microbes (Bacteria, fungi & algae) during production, usage or storage. The microbial attack of textiles leads to quality losses due to changes of color and appearance or to reduction in strength and can result in unpleasant odor formation. Moreover, since microbes absorb to textiles, there is a risk of contamination and infection. As increasing demand develops for imparting antimicrobial active agents to textile materials (Fabrics and non-wovens) by chemical and natural ways in order to create additional properties (Functional textiles).With synthetic and natural fibers blends, this may create a better hydrophilic behavior, physical and chemical properties. Natural and chemical antimicrobial finish in two concentrations i.e. 1 per cent and 2 per cent were applied on the all blends by pad dry cure and exhaust method. According to standards (AATCC-100-2004), qualitative testing was also done to evaluate antimicrobial property against Staphylococcus, Klebsiella, and Candida for controlled samples of 1 per cent finish and 2 per cent finish.

Natural compound (Clove oil) and chemical compound (N9) were selected as antimicrobial finish for this study. Clove oil was applied through pad dry cure method and N9 silver finish through exhaust method.

The Qualitative testing of antimicrobial finish was done on the finished sample and controlled samples. The testing of antimicrobial property against bacteria and fungus was done as per the standard AATCC 100-2004.

The antimicrobial property of 30:70 NYCO fabric was tested on natural antimicrobial finish (Clove oil) against Gram Positive Bacteria (Staphylococcus). The zone of inhibition was absent in controlled condition, 2.5mm in 1 per cent finish, 4mm in 2 per cent finish for Gram negative bacteria. In case of Klebsiella, it was absent in controlled condition, 2mm in 1 per cent finish, 4.5mm in 2 per cent finish and for fungus (Candida), it was absent in controlled condition, 1mm in case of 1 per cent finish, 3mm in 2 per cent finish. In all of that 2 per cent finish has good antimicrobial property.

The antimicrobial property of 30:70 NYCO fabric was tested on chemical antimicrobial finish (N9) against all microbes. The zone of inhibition of staphylococcus was 1.5mm in 1 per cent finish, 2mm in 2 per cent finish, Gram Negative Bacteria (Klebsiella) was 1.5mm in 1 per cent finish, 3 mm in 2 per cent finish and fungus (Candida) was, 1mm for 1 per cent finish, 2mm for 2 per cent finish. In all of that, 2 per cent finish had good antimicrobial property. So, it can be concluded that natural antimicrobial finish had good antimicrobial property in comparison to chemical antimicrobial finish and it should be applied on fabrics to protect fabrics from microbes.

Microbes free military men save us better.

References

Gulrajani ML (1999) Nat Dyes for Textile Application. In Chavan RB (Ed) Chemical Processing of Handloom Yarns and Fabrics, IIT, Delhi.

Gulrajani ML and Rastogi (2000) Application of Lac Dye on Cationised Cotton. Colorage 47(4): 36-40.

Kumar GR and Krishnaveni V (1992) An Ecofriendly Herbal Antimicrobial Finish on Cotton Fabric Using Aloe Barbadensis Miller (Aloe Vera), Available at www.fibre2fashion.com/industryarticle.

Sathianarayanan MP, Bhata NV, Kokate SS and Walunj VE (2010) Antibacterial Finish for Cotton Fabric from Herbal Products, Available at nopr.nircair.res.in/bitstream.

articles.textileclass.com

www.aegisasia.com/Comparision-of-antimicrobials.html